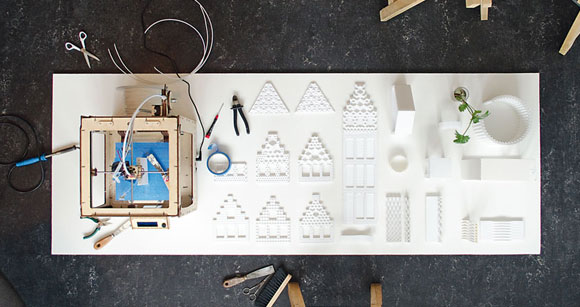

A view of DUS architects’ studio. Photo by Hans Vermeulen

The April 2013 issue of Domus features my story on DUS architects’ KamerMaker — a large-scale, mobile 3D printer — and their project to built the world’s first 3D printed canal house, room by room, in the north of Amsterdam. The project seeks to revitalize a run-down area in the north of the city, and I was fortunate to visit DUS’ studio on a grey March morning to see the KamerMaker for myself. The full feature is available to read online over at Domusweb, and an excerpt can be seen after the jump.

Since last fall, DUS has significantly raised the stakes. Soon the KamerMaker will be moved to the other side of the canal that borders the Open Coop, where a construction site will come to life, and the KamerMaker will print “the house of the 21st centuryâ€, a fully 3D-printed structure shaped like an Amsterdam canal house. This formal dimension seeks to evoke the local context and enhance the value of the northern area of the city — as part of a larger project titled The Northern Canal Belt — while advocating a specific, one-off type of ornamentation that, according to DUS, has been lost in the age of mass production.

The studio has made use of their now solid relations with diverse partners, from the municipality to construction companies, and is taking the first steps into what may potentially become the synthesis of all the work they have developed so far, creating an experimental research site where multiple stakeholders — including sponsors and community members — are invited to intervene in a co-creation process, where progress is measured and evaluated step by step.In May, DUS hope to launch what they call a “construction site 2.0â€, an event and education space where every print that comes out of the KamerMaker will be exhibited, celebrated and commented upon. The first built elements — to be completed by the end of the year — will be a lavishly ornamented facade and the first of the house’s 12 spaces, the Welcoming Room. Heinsman points out how “the rooms are metaphors for researchâ€, focusing on more practical concerns regarding the limits of 3D printing and material recycling, as well as larger issues such as energy consumption and policy-making.

For now, DUS are extensively printing facades and components on a Ultimaker at the scale of 1:20, testing durability, ornamentation and structural issues. Inside one of the meeting rooms, a desk is filled with tiny white polypropylene experiments, cube- and rhombus-filled micro facades. Were it not for the small 3D printer whizzing in the background, this could be an artisanal workshop of a century ago. “It’s just the beginning,†declares Heinsman. “We are laymen, and we are learning by doing.â€